MegaBRIX® is Wahl’s branded name for any full or partial precast furnace. Whether new construction, lining replacement or lining repair, MegaBRIX® Precast Furnace Linings provide superior lining performance, ease of installation and quick turnaround.

TURNKEY INSTALLATIONS, REPAIR & MAINTENANCE

- Extensive Project management experience within the aluminum industry.

- Ability to utilize local labor or prequalified Wahl contractors.

- Projects range from maintenance repairs to complete installations.

TURNKEY INSTALLATIONS, REPAIR & MAINTENANCE

UPPER & LOWER WALLS

Upper Walls

- Products range from 60 to 70 percent alumina.

- Can be precast, cast-in-place or shotcrete.

- Good refractory thermal conductivity resulting in low shell temperatures.

Lower Walls

- Products range from 70 to 90+ percent alumina.

- Non-wetting additives are resistant to 2200° F.

- Excellent corundum attack resistance at the furnace belly band.

- Erosion resistant materials available for EMP and Sidewell applications.

UPPER & LOWER WALLS

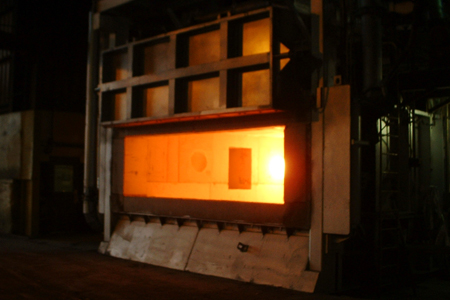

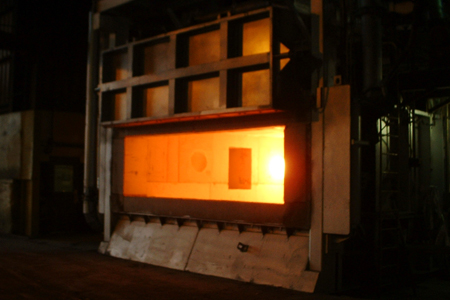

ROOFS

- Modular design allows for fast installation.

- Engineered and designed for individual furnaces.

- Allows for growth and expansion during furnace heat up.

ROOFS

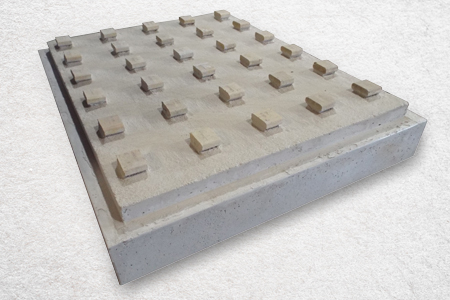

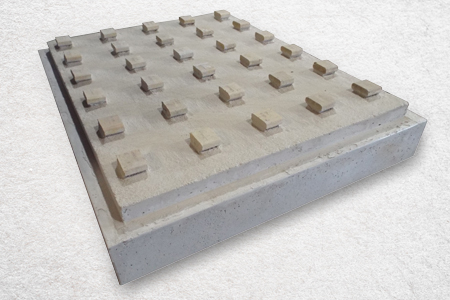

HEARTHS

- Products range from 70 to 90+ percent alumina.

- Erosion resistant materials available for Electro-Magnetic Stirring.

- “Ultra” materials available for impact resistance.

HEARTHS

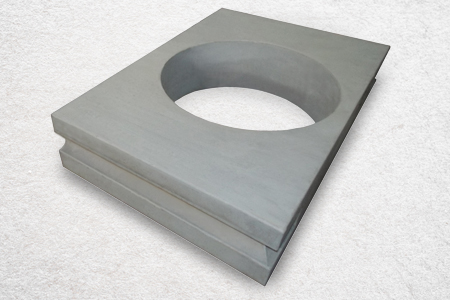

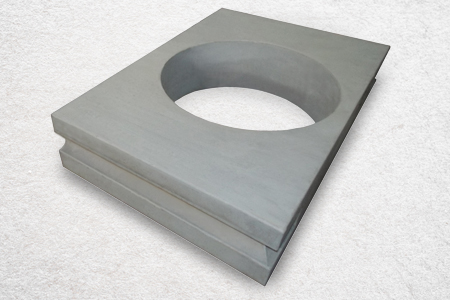

SUB HEARTHS

- Non-wetting insulating castable for back-up lining.

- Precast or cast-in-place.

SUB HEARTHS

POUR SPOUTS

- Erosion resistant materials available.

- Non-wetting additives are resistant to 2200° F.

- Wire can be added to minimize thermal shock.

POUR SPOUTS

BREACH WALLS

- Engineered furnace openings to ensure proper alignment.

- Material zoning from furnace to breach.

BREACH WALLS

CHARGE WELLS

- Erosion resistant materials.

- “Ultra” materials available for impact resistance.

- Non-wetting additives are resistant to 2200° F.

CHARGE WELLS