Wahl precast cooler components eliminate inadequate dry-out, which extends service life. Engineered Bull Nose blocks roof blocks solve anchoring and support issues experienced in many coolers. Precast wall blocks and cooler curb blocks are pre-fired for optimum refractory properties and resistance to abrasion. Blocks are positioned quickly and can generate savings in installation and dry-out time and costs.

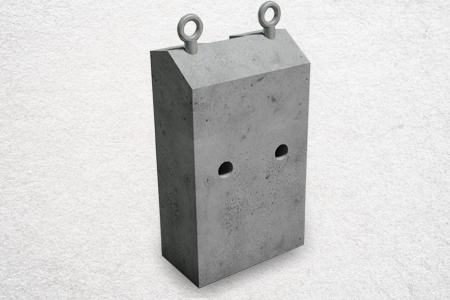

The bullnose section of a clinker cooler exposes the refractory lining to a particularly difficult combination of mechanical stresses, high temperature, abrasion and alkali salt attack. This difficult application is best served through the use of engineered precast bullnose blocks which can take the heat. With extensive experience with bullnose refractory over many years, Wahl has developed a cost-effective solution which can be retrofitted to many cooler designs.

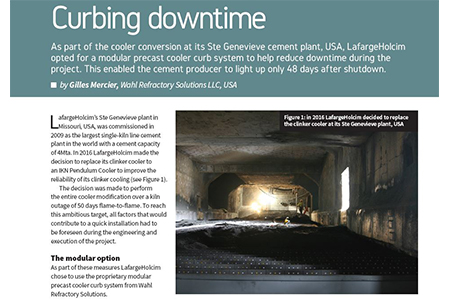

BULL NOSE

Wahl precast cooler roof blocks have successfully eliminated refractory failures and reduced maintenance costs in coolers for many years. Below is an example of a test panel of Wahl cooler roof blocks installed in June 2008 in a cement plant in the USA. After more than six years in service, the test panel was inspected in 2015 (right photo) and exhibited smooth wear and good remnant thickness. The adjacent section of cooler roof was lined with a competitor’s castable refractory and needed annual maintenance and repair.

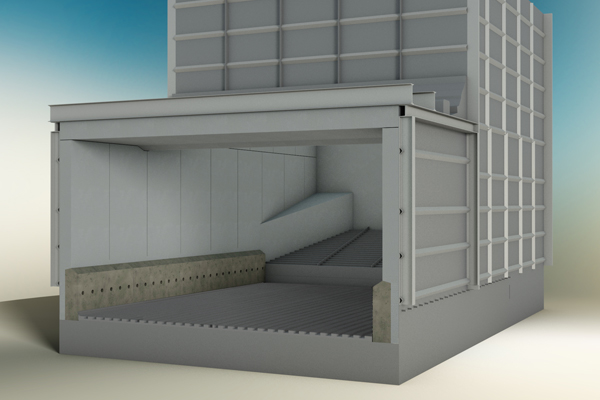

COOLER ROOF

Wahl Refractory Solutions produces modular roof blocks that can line cooler walls and firing hoods. These precast blocks can be zoned with different grades of refractory to address areas of increased wear, and with the optimized physical properties of a precast refractory that is cured and baked out in our controlled manufacturing process.

COOLER WALLS

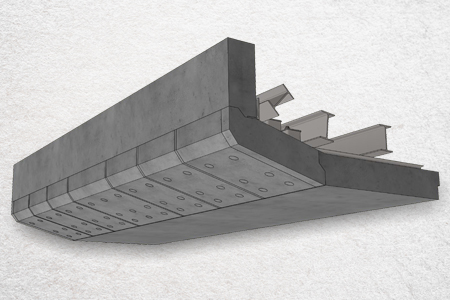

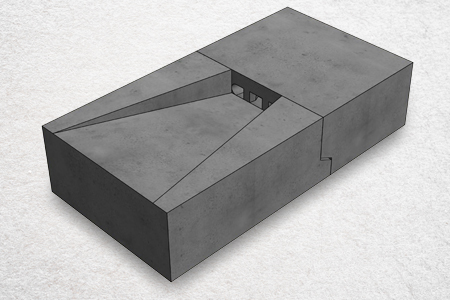

Cooler curb is a commonly used name in the cement industry for the lower part of the cooler walls which are at the level and below the clinker bed. This part of the refractory is exposed to high temperatures and abrasion from the hot clinker traveling down the cooler. Wahl has developed an engineered precast cooler curb block which has been successfully used in modern clinker coolers. Photograph on the right is of a recent inspection of Wahl precast cooler curb blocks after 5 years in service in a modern 1.7million ton/yr cement kiln in the USA.

COOLER CURBS

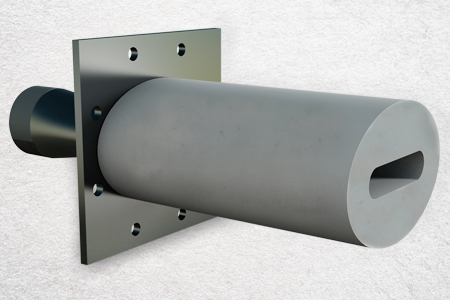

- Wahl Precast Blaster Nozzles are designed to outlast steel castings.

- Offer improved resistance to high-temperature and corrosive environments.

- Drastically reduce maintenance costs.

- Standard lengths are stocked for quick delivery.

BLASTER NOZZLES

- Outlast conventional protection tubes by as much as 10 times.

- Wahl SIFCA® material exhibits greater strengths and resistance to impact at high temperatures.

- Outperform conventional protection tubes, resulting in reduced inventory of tubes and thermocouples.

- Proven to be a cost-effective solution to the industry’s demands.

THERMOCOUPLE PROTECTION TUBES