Using the latest developments on refractory castable technology, Wahl has specially formulated monolithics for use in cement plant preheaters. They provide maximized resistance to alkali attack, along with optimized abrasion resistance and hot strengths.

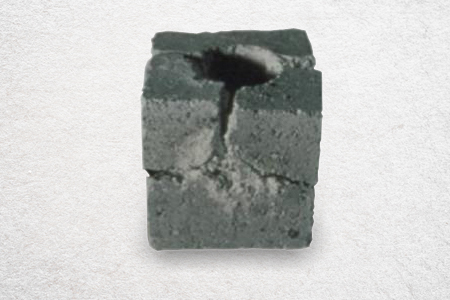

In today’s modern cement kilns, alkali chlorides and sulfates are introduced through the use of alternative fuels and raw materials, leading to excessive buildups in the riser duct and alkali attack of preheater refractory linings. Through laboratory experiments and the use of a proprietary ‘exaggerated’ alkali cup test, Wahl’s R&D laboratory was able to screen refractory raw materials and compositions to optimize resistance to alkali attack and resistance to buildups at temperatures up to 1100oC.

CUP TEST

WalFlow KLN60 is designed to withstand the highly alkali and abrasive environments found in cement preheater towers, including risers, feed shelves, and cyclones. This product also resists build up. WalFlow KLN60 is a 60% alumina mullite-based ultra-low cement, self-flowing refractory castable. This product can be placed via pumping, shotcreting, or vibration cast.

WALFLOW® KLN 60

For more severe applications, WalFlow RSR was designed to have optimum resistance to thermal shocks and highly alkali and abrasive environments found in cement preheater towers, including risers, feed shelves, and cyclones. This product has very high resistance to buildup attachment, facilitating buildup removal.

WalFlow RSR is a mullite-zirconia based ultra-low cement, self-flowing refractory castable. This product can be placed via pumping, shotcreting, or vibration cast.

WALFLOW® RSR

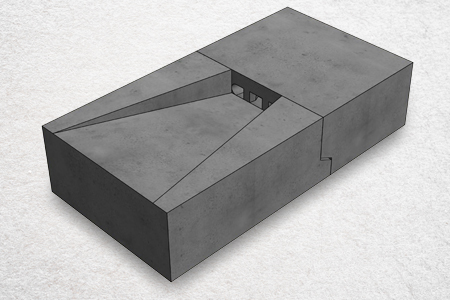

The newest generation of Wahl’s high performance GemStone line of products. Wahl’s GemStone G2 product is known the world over as the optimal choice for precast T/A Dampers. Our newest product GemStone G3 improves on its predecessor’s properties including improved abrasion resistance, mechanical properties including higher crushing strength and unsurpassed hot modulus of rupture at 1100oC. It demonstrates industry leading thermal shock resistance with 0% loss of strength by ASTM C1171 thermal shock standard testing. Alkali resistance has also been optimized through Wahl’s ‘exaggerated’ alkali cup test. GemStone G3 is available in the precast form such as T/A Dampers, Blaster Nozzles, Wall Blocks, Bull Noses, etc.

GEMSTONE® G3

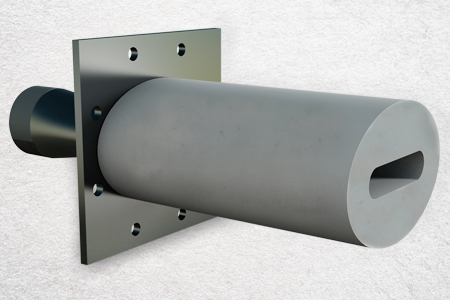

- Wahl Precast Blaster Nozzles are designed to outlast steel castings.

- Offer improved resistance to high-temperature and corrosive environments.

- Drastically reduce maintenance costs.

- Standard lengths are stocked for quick delivery.

BLASTER NOZZLES

- Outlast conventional protection tubes by as much as 10 times.

- Wahl SIFCA® material exhibits greater strengths and resistance to impact at high temperatures.

- Outperform conventional protection tubes, resulting in reduced inventory of tubes and thermocouples.

- Proven to be a cost-effective solution to the industry’s demands.

THERMOCOUPLE PROTECTION TUBES